On to Section 21: Flaps.

The work accomplished on this post was completed between October 24th and 31st.

As with every section that has a left and right, the plans only provide building instructions for the Left (unless otherwise noted).....in this case the Left Flap only. Additionally, as with every section, the plans start with preparing the parts and pieces that make up whatever you are building.....and this section is no exception.

Below are the six FL-1007-L and FL-1007-R Hinge Brackets. The plans state to adjust the flanges to be parallel with the part body if/as required. I found that none of the 12 Hinge Brackets required any adjustment and were all parallel.

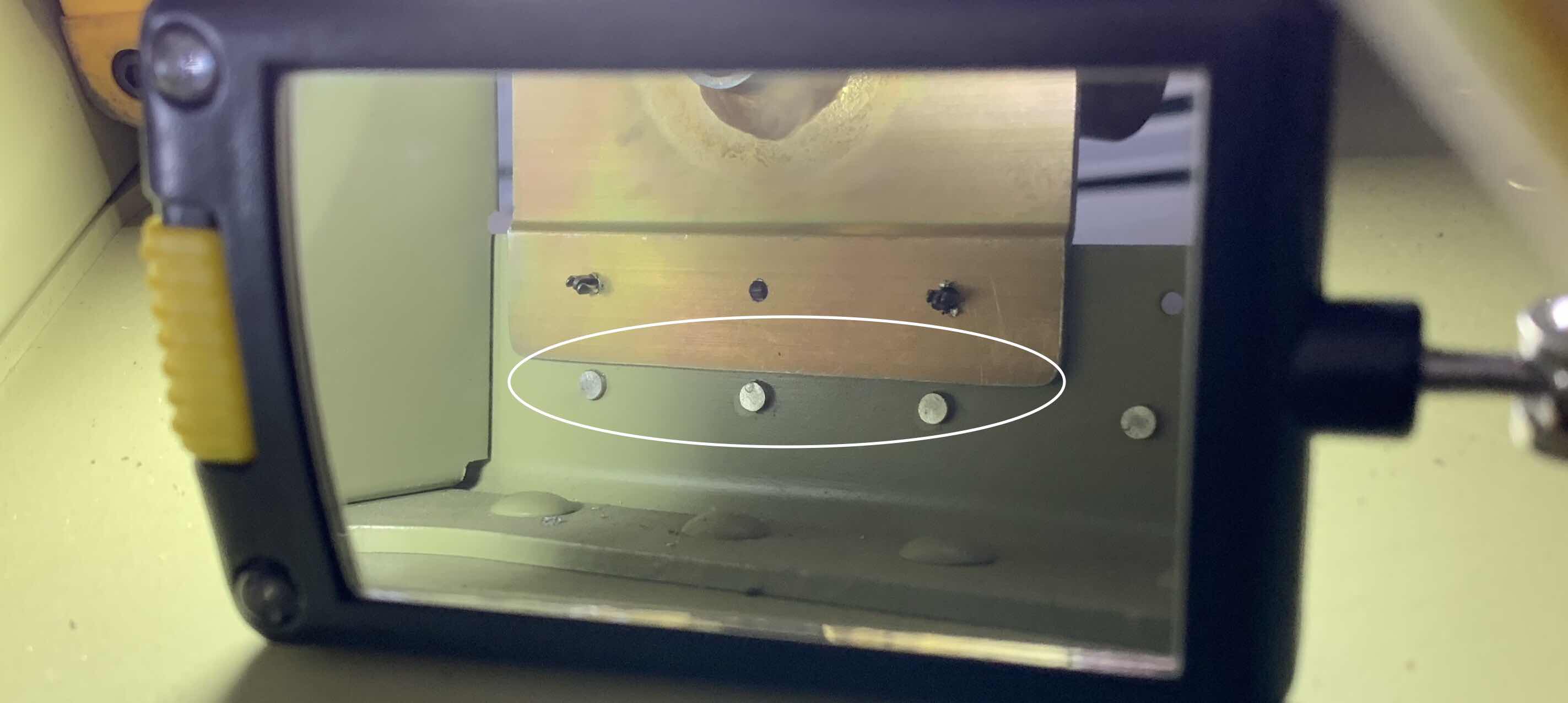

The picture below looks a little...weird, but I can explain. If you look at the FL-1007-L Flange with the two clamps on it, you can see the blue line running horizontally. This blue line, and four hole pattern, was drawn following the dimension called for in the plans. Once the holes were marked, they were drilled with a #40 and deburred. After all four holes were drilled, a second FL-1007-L Hinge Bracket was clamped to it. (Since the FL-1007-L Hinge Brackets are the “same” piece, in to clamp them together, I had to revers the piece as shown below). Lastly, the four holes were match-drilled to the additional Hinge Bracket. This process was repeated for the remaining FL-1007-L Hinge Brackets.

*****The FL-1007-R Hinge Brackets DO NOT get drilled at this time*****

Clecos installed after all four holes were match-drilled.

All six FL-1007-L Hinge Brackets after being match-drilled and deburred. The Bracket on the far left was used as the “template” for the other five Brackets.

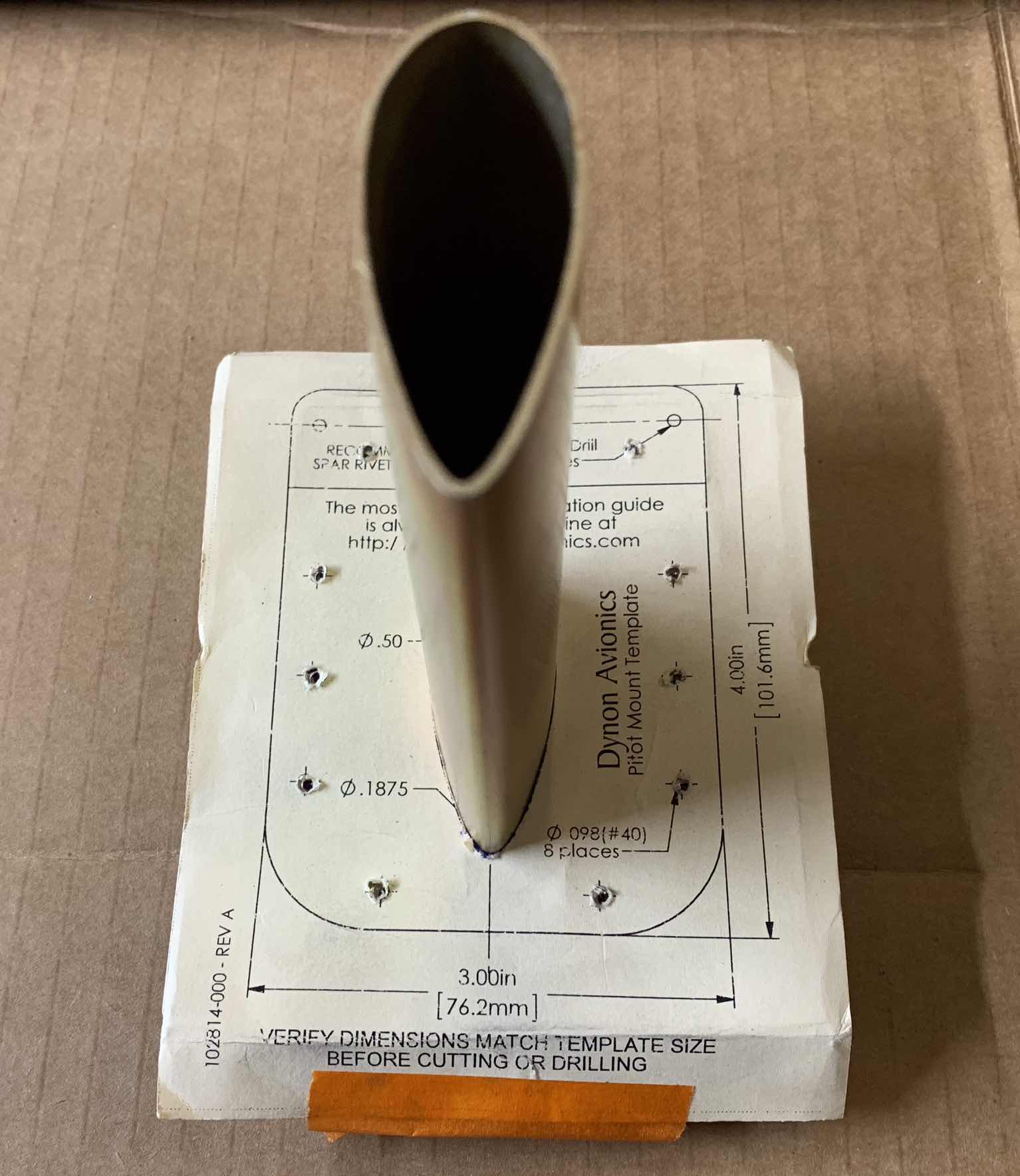

All the FL-1004-L & -R Nose Ribs were straightened and fluted as necessary and deburred. Next, two of the FL-1004-L, two FL-1004-R Nose Ribs, and four FL-1006 Doublers were clecoed toghether to form the Outboard Rod End Rib Subassemblies. Here is what it looks like on the plans.....

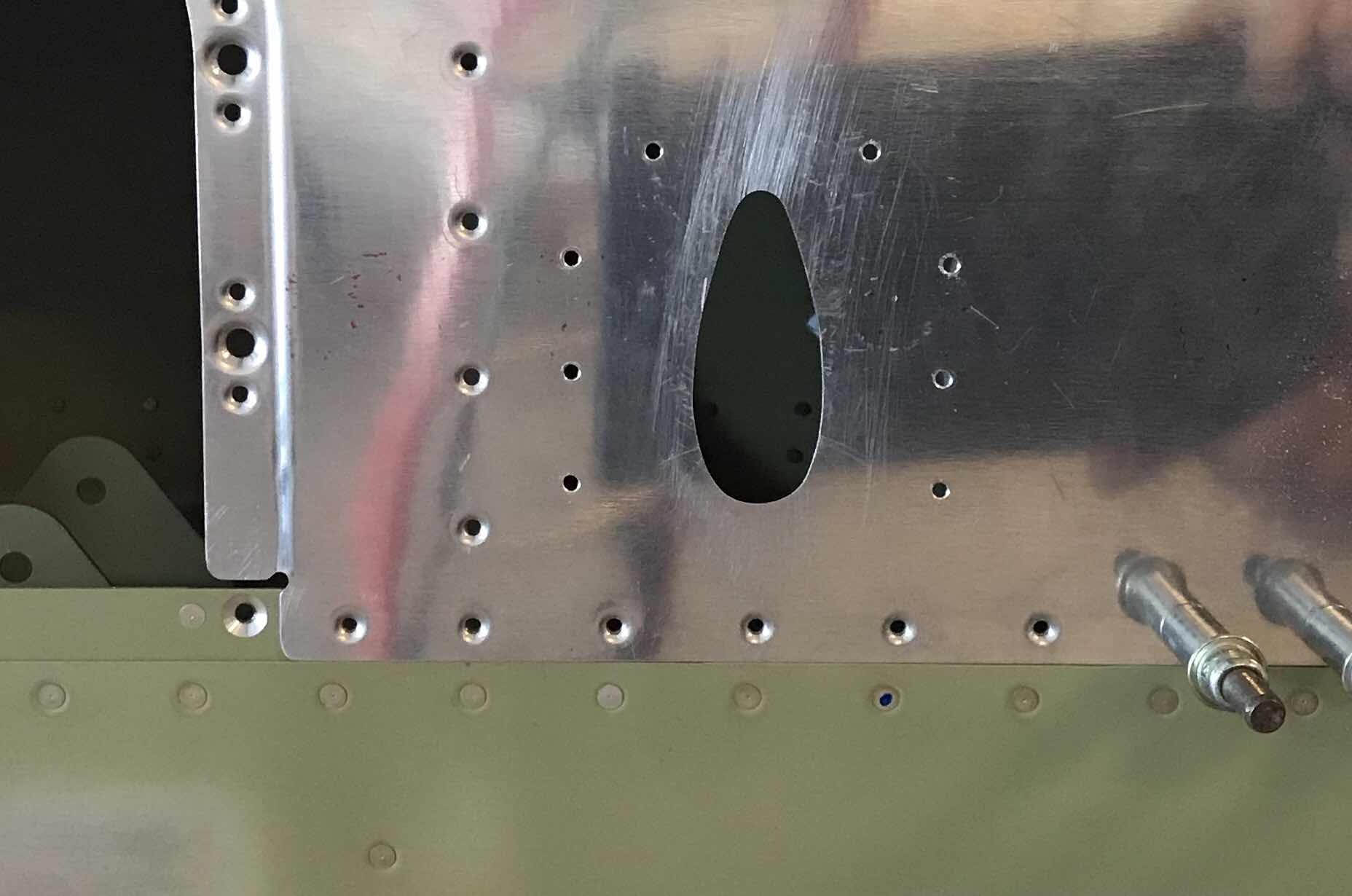

The four #40 holes (that will attach the nutplate) were match-drilled using the Doubler as a guide. Additionally, the two 1/4 holes in the Doublers were final-drilled with the corresponding #30 hole in the Nose Rib. Lastly, the four #40 holes were machined countersunk for a AN426AD3 rivet. After all the holes were drilled, the Subassemblies were disassembled, deburred, and re-clecoed. Below is an example of all the competed work listed above.

The Inboard Robb End Rib Subassemblies were prepared in the same manner as described above with one exception. The four #40 holes on the FL-1006 Doublers are ignored and not prepared for nutplates. Here is what it looks like in the plans.....

Next, all the #30 holes in the FL-1004-R Nose Ribs and the Inboard and Outboard Rod End Rib Subassemblies were final-drilled. Lastly, all the edges were cleaned in the parts shown below.