I had to prepare and prime some parts for Part 1 of the Canopy and Window, so I deceived to prepare a few of the cabin area cover plates. The parts didn’t take much time to prepare and were finished quickly.

Here is the F-01440-L Seat Ramp.....

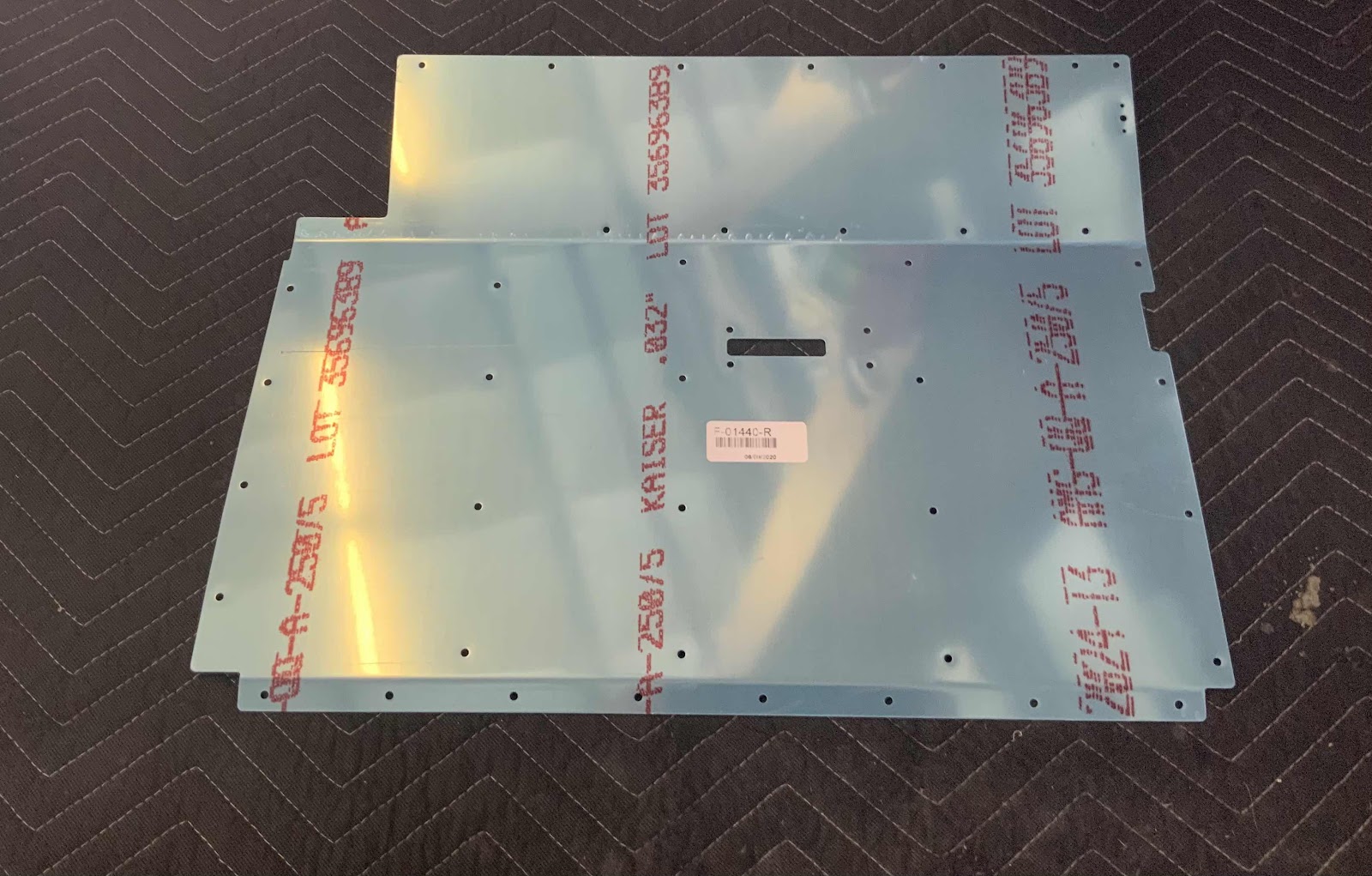

.....the F-01440-R Seat Ramp.....

.....and both of the Seat Ramps after being treated with Alumiprep, Alodine and Akzo Primer.

This is the F-01436-R Control Column Cover.....

.....F-01436-L Control Column Cover.....

.....and both Control Column Covers after being treated with Alumiprep, Alodine and Akzo Primer.

Just a little personal motivation.....here are the Control Column Covers and Seat Ramps sitting in place in the cockpit.

Lastly, these parts actually should have been included in the Canopy and Window section, but it’s only a couple parts and they were completed very quickly.....so, I included it in this post. These parts have been treated with Alumiprep, Alodine and Akzo Primer.

C-01413 Inboard Hinge Intercoastal (top two on the left)

C-01414 Outboard Hinge Intercoastal (top two on the right)

C-01429 Latch Bellcrank Angles (four in a row)

F-01474A-L & -R Stiffener Angles (bottom two)

Lastly for this session, I painted the Latch Bellcrank Angles and Stiffener Angles the same grey color as the remainder of the interior.