I spent this session working on the F-01474-R and F-01474-L Top Side Skins. The plans tell you to dimple all #30 and #40 holes (except as noted) in both Skins for exterior flush mounted rivets. There are 14 #40 holes in the forward "curve" that do not get dimpled. In the aft section of the Skin there are also two holes that do not get dimpled. The plans tell you not to dimple one of the holes; however, the other is a #27 hole. Don't dimple either.

As the instructions recommended, I put tape on the holes that do not get dimpled to prevent accidentally doing it. The orange tape covers the holes in the forward "curve".

Here is the hole the plans tell you not to dimple (under the orange tape). It appears a nutplate will be installed here at some point.

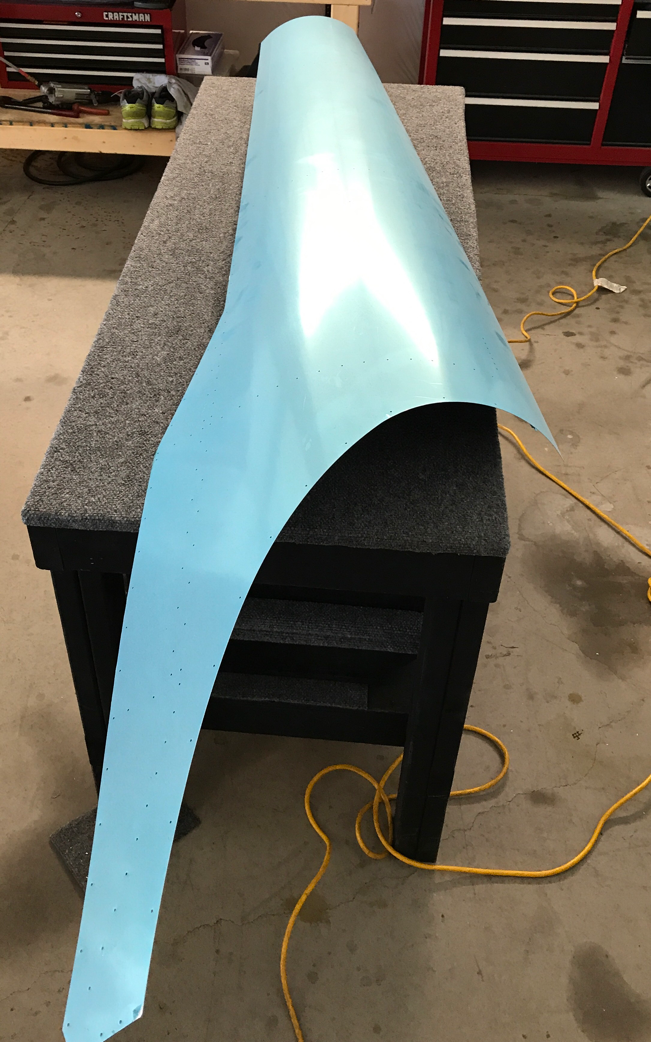

This is the F-01474-R Side Top Skin with the blue protective coating prior to being removed.

So, all #30 and #40 holes (except as noted in the plans) were dimpled and all the edge work was completed on both Side Top Skins. During the next session, I will complete the Alumiprep, Alodine, and Akzo Epoxy Primer.