I started today’s session by making sure the four W-1025A Flap Hinge Brackets were straight and flat. They come in a package of four and all four needed slight adjustments. Section 5.13.1 of the plans discusses how to straighten thick aluminum parts.....I followed the WHANG method!

Here is one of the Flap Hinge Brackets.

The W-1025B-R / W-1025B-L Flap Hinge Ribs and W-1025A Flap Hinge Brackets were clecoed to the W-1011-L / W-1011-R Inboard Wing Ribs. Now, the 14 common #30 holes are match-drilled and the two alignment holes are final-drilled #30. (The two below are for the Left Wing and the process will be repeated for the Right Wing).

The aft Flange (but not the radius of the Flange) had to be removed from one of the W-1012-R Outboard Wing Ribs as shown in the excerpt below.

I used my Dremel tool to cut off the Flange just below the holes and used a fine file and 220 grit sandpaper to make the final a shape. Here is the result.

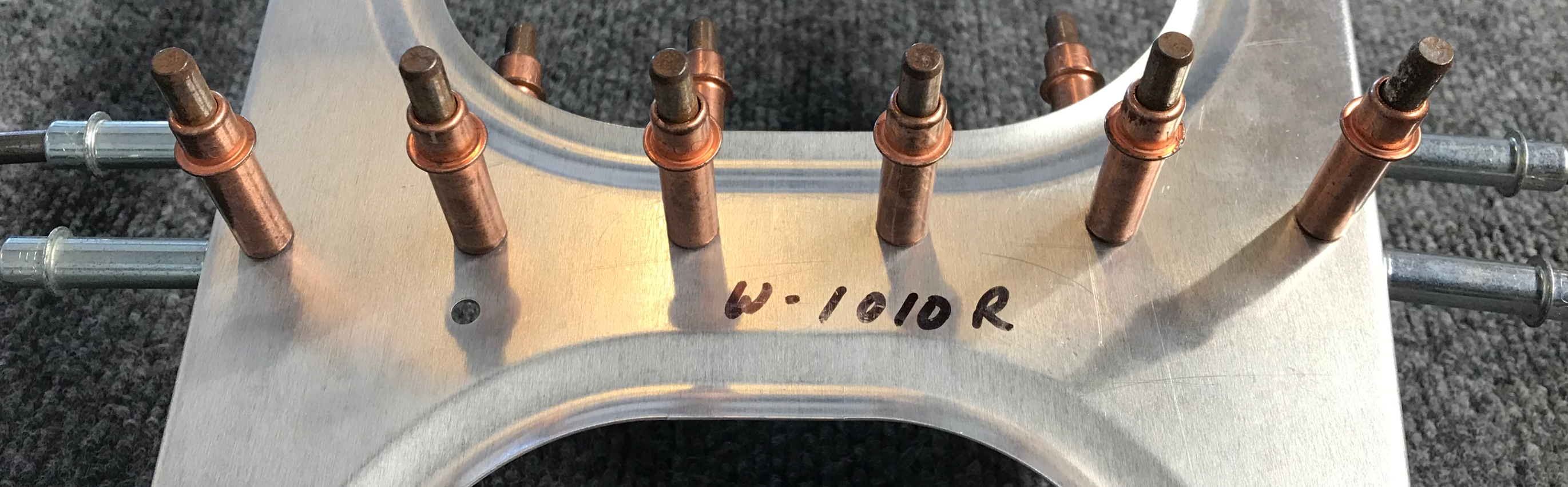

Next is to remove all the bolts, nuts, and washers from the Left Main Spar Assembly and set them aside for later use. There were 11 bolts on the Upper Flange (top row) and 11 bolts in the Lower Flange (bottom row).

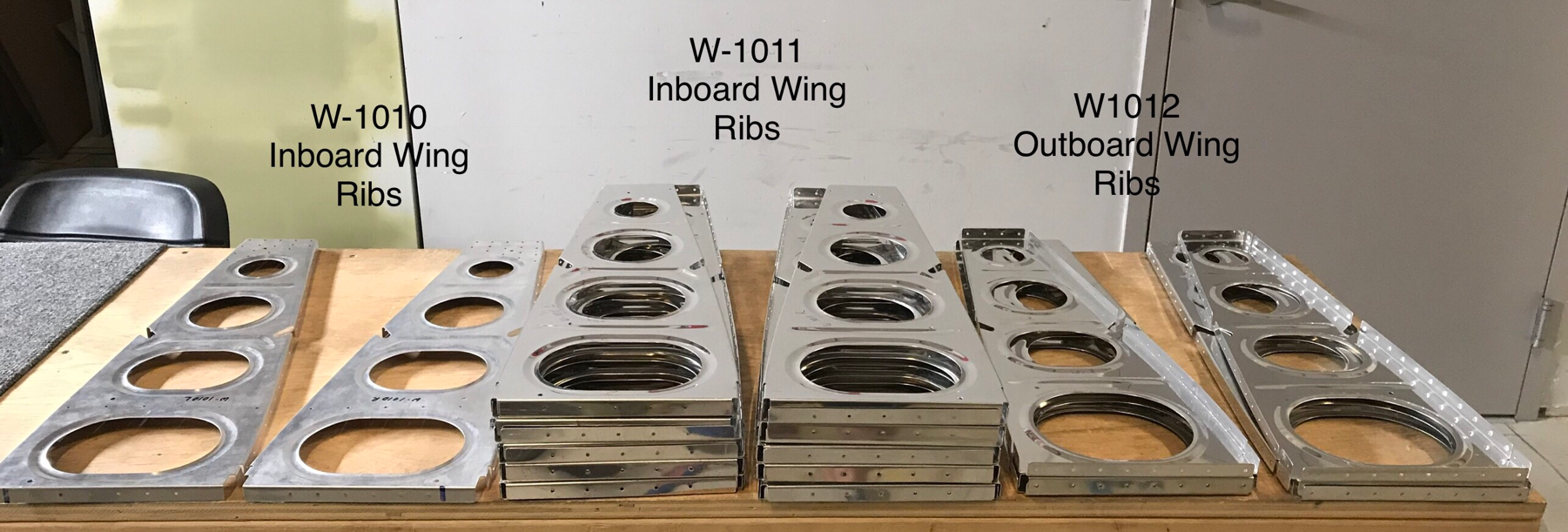

After removing all the bolts, the W-1010-R Inboard Wing Rib, W-1011-L & -R Inboard Wing Ribs, and W-1012-L & -R Outboard Wing Ribs were clecoed to the Left Main Spar Assembly. The picture below shows all 14 Ribs clecoed to the Left Main Spar. According to the plans, a whole lot of drilling is about to happen.

#12: Upper and Lower holes of the Rib Flanges that will use bolts/nuts to attach to the Main Spar Assembly

#30: All remaining common attach holes in the Forward Flange of the Ribs and Web of the Main Spar Assembly

#40: All common attach holes in the Upper and Lower Rib Tabs and Flanges of the Main Spar Assembly

****Then, of course, everything will be disassembled and you have to debur all the freshly drilled holes****