After watching the few college football games today, I found myself sitting at home bored. So, what do you do? You go work on the airplane (Ribs) again!

I finished the last two W-1012 Ribs and now all 28 Wing Ribs have had the edges cleaned, upper and lower flanges final-drilled to #40, and the lower flange #40 holes were dimpled. (Again, I am using the Substructure Dimple Dies from Cleavland Aircraft Tool for all substructure parts).

It took roughly 20 hours to complete all 28 Wing Ribs. I know this is probably longer than some builders, but because I personally chose to hand sand the Ribs, it took additional time.....and I’m okay with that.

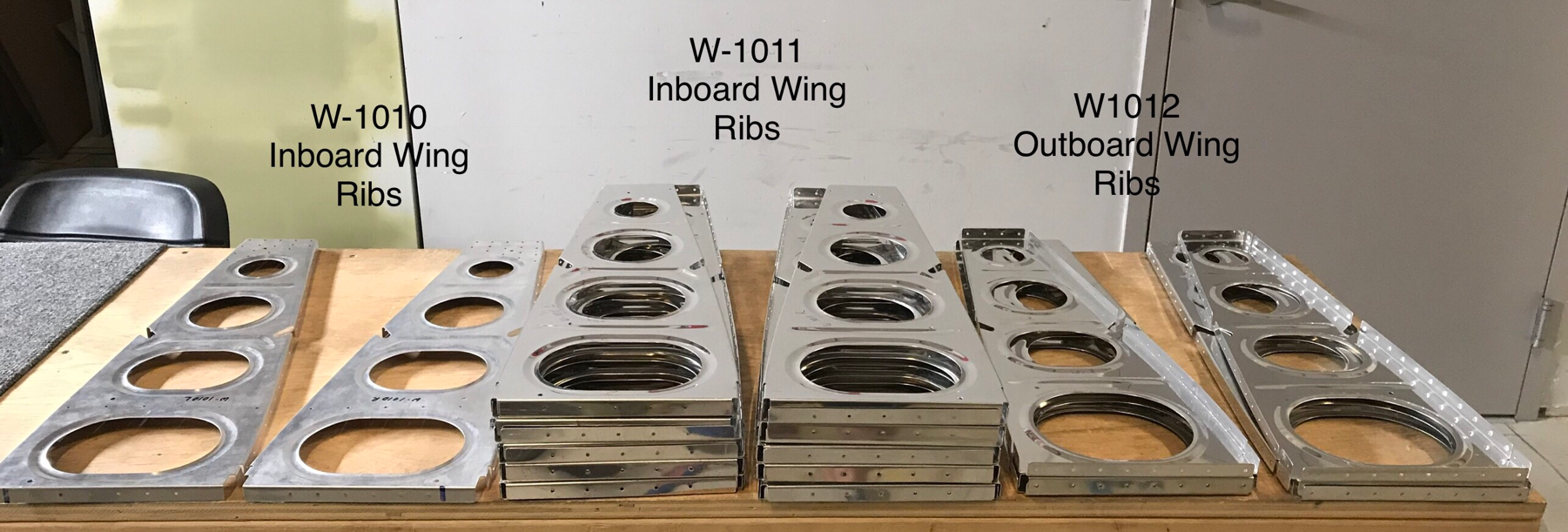

The picture shows:

(2) W-1010 - Inboard Ribs, one on each Wing

(20) W-1011 - Inboard Ribs, 10 on each Wing

(6) W-1012 - Outboard Ribs, three on each Wing

They are designated left and right Ribs and they are arranged appropriately below in each group.....left on the left and right on the right.

As shown in Part 1, these Ribs will be only be installed on the aft side of the Main Spar Assembly. Additional Ribs will be used on the front to include the Fuel Tanks.