Yesterday was prime day.....today is countersink day. Below are the F-01485-L & -R Center Section Side Plates. All the #30 and #40 holes had to be countersunk (except the ones covered in orange tape) to accept the .032 Side Skins. The large grouping of holes on each piece are the #30 holes and the rest are #40. Once the stops are set on the countersink, the process went pretty quickly.

I used a couple of boards (actually wood from breaking down the crate one of the kits came in) on either side of the hole line to be countersunk for support and clamped the assemblies to the table.

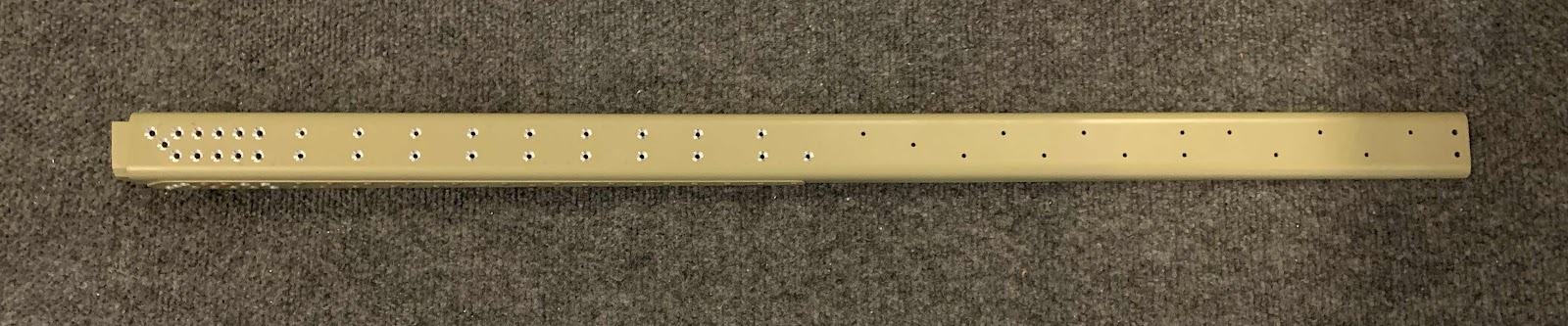

Pictured below is the Left Lower Longeron Assenbly. Many of the holes in this assembly also needed to be countersunk. The group of holes on the left are the #30 holes and the rest are #40. As you can see, only about half of the #40 holes get countersunk.

Below is the Right Lower Longeron Assembly. After countersinking the appropriate holes, I discovered a “situation” I’m not entire comfortable with. If you look at the three rivets I have inserted in three of the holes, you can see two of them don’t look right. The rivet on the far right fits into the hole with no “gaps” around the rivet. The left and center rivets have large “gaps” around the them. After inspecting the remaining holes, many showed “gaps” around the rivets and looked oval (you can see this in the picture). The best I can guess.....I wasn’t perfectly straight when these holes were Match-Drilled to 1/8”. THIS IS OBVIOUSLY UNACCEPTABLE! I could call Van’s and maybe get guidance on a “fix”, but it wouldn’t be right. This area will be subject to higher stress loads and I want it to be built correctly. So, since there are only three total pieces that make up this Assembly, I ordered replacement parts and will rebuild the Assembly correctly.

Below is the Left Upper Longeron Assembly and also required countersinking. The six holes on the far left (bottom) are the #30 holes that needed countersinking (upper holes are not countersunk). The remaining holes in the Assembly are #40 and all required countersinking. The Right Upper Longeron Assembly was completed the same way.

Since I discovered the problems holes in the Right Lower Longeron Assembly, I inspected all the holes in the other three Longeron Assemblies. All of the other holes were perfect and no “gaps” were present around the rivets.