I completed the construction of the Wing Cradles during the last session. Now, the plans have you move on to preparing the W-1008 Splice Ribs and W-1009 Outboard Leading Edge Ribs. Pictured below, the two Splice Ribs are on the right (one for the Right Wing and one for the Left Wing) and the Outboard Leading Edge Ribs are the stack of Ribs on the Left (six for the Right Wing and six for the Left Wing).

Now, all the Flange angles need to be adjusted, fluted, and straightened. Additionally, all the #30 and #40 holes in the Flanges need to be Final-Drilled to the appropriate size. I have also decided to complete all these step for both Wings as the same time. So, all 14 Ribs will get prepared now at the same time.

Two W-1009-L Leading Edge Ribs (for the Left Wing assembly) and two W-1009-R Leading Edge Ribs (for the Right Wing assembly) have to be modified per the dimensions provided in the table below. These Ribs must be notched to fit around the Spar Bars and the rivet heads on the Main Spar assembly. Additionally, because the Main Spar Bars are stepped (spanwise thickness changes) two different modified Ribs will be required.

These are the two W-1009-1L/R Ribs after being marked per the table. The material in the areas marked in black at the top and bottom of the Rib will have to be removed.

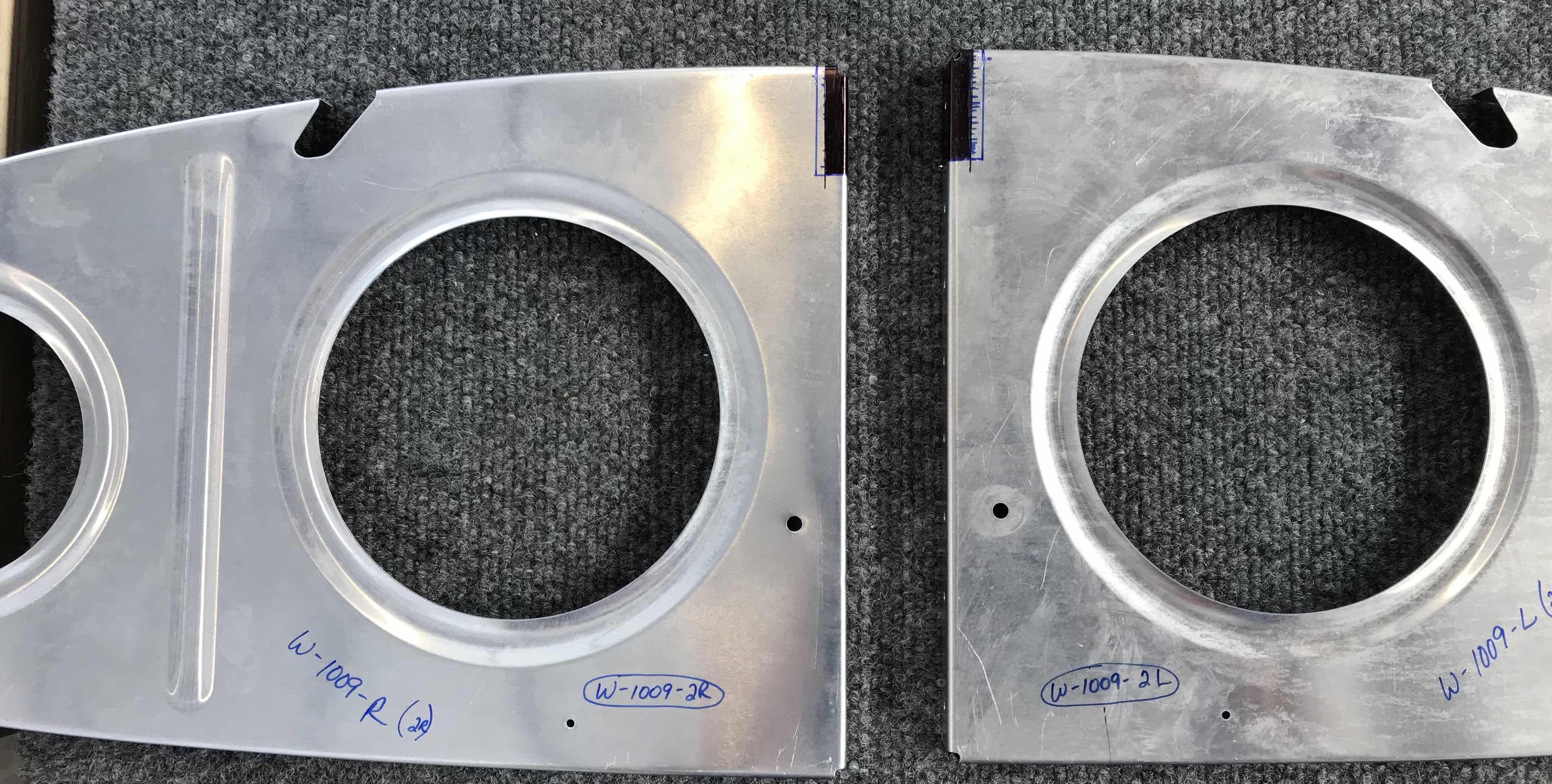

These are the W-1009-2L/R Ribs after being marked per the table. These Ribs will only have material removed from the top of the Rib (also in black).

I’ll pick it up here during the next session.