After completing the match-drilling described in Part 3, the Wing Tip Fairing was removed from the Wing. After some clean up, the #40 holes in the Leading Edge Skin, Top Outboard Wing Skin and Bottom Outboard Wing Skin were deburred, final-drilled #27 and dimpled for #6 screws. Here is an overall look at the completed work.

Now, moving on to preparing the Wing Tip Fairing for the 42 K1000-06 nutplates. The #40 match-drilled holes from Part 3 will be used to locate the nutplate attach holes for the nutplates. The plans say to use temporary screws to hold the nutplates in place. However, #6 screws won’t fit through a #40 hole. So, I decided to go ahead and final-drill these holes to #27 to allow a #6 screw to fit (the plans have you do that anyway in a few steps, so I just did it “early” I guess).

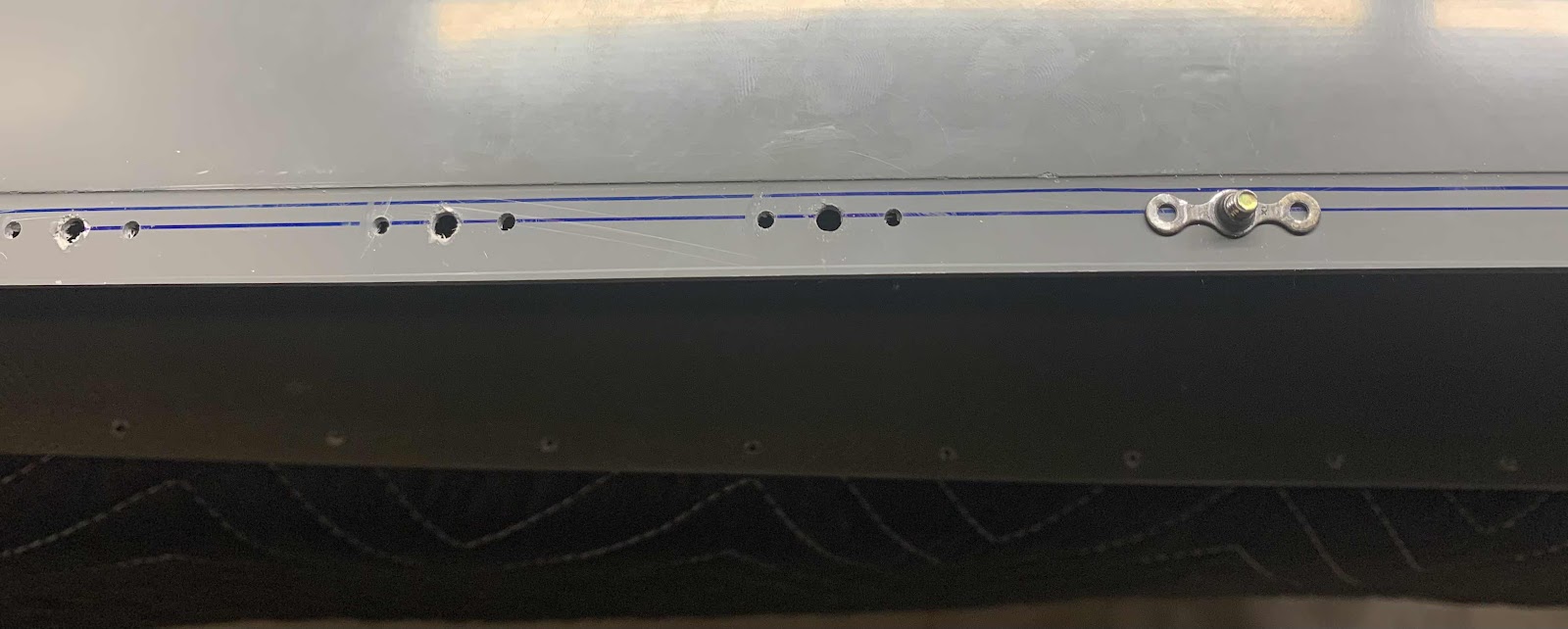

To start, I used a flexible ruler to draw a line along the length of the Fairing to connect all the center screw holes. Then I inserted a #6 screw (backwards through the hole) and attached the nutplate (on the incorrect side). This allow you to line up the nutplate attach holes with the previously drawn line to get the nutplates as straight as possible. The picture below shows an example of this process.

I ran out of time tonight to compete the process for the entire Fairing, but will pick up here during the next session.