In Part 11, I started dimpling the F-01475A Skin Doubler. I was able to dimple all the #30 holes, but not the #40 holes near the edge (with a standard sized dimple die set). If I used a standard die, it would deform the bend in the edge of the Doubler. In order to prevent the deformation of the material, a reduced diameter dimple die would need to be used. So, I ordered one from Cleaveland Aircraft Tool. In the picture below, you can see the standard die on the left and a reduced diameter die on the right.

Here is what the two dies look like on the Doubler. The edge of the standard die touches the bend in the Doubler and would deform the bend during the dimpling process. The reduced diameter die is small enough to prevent any damage.

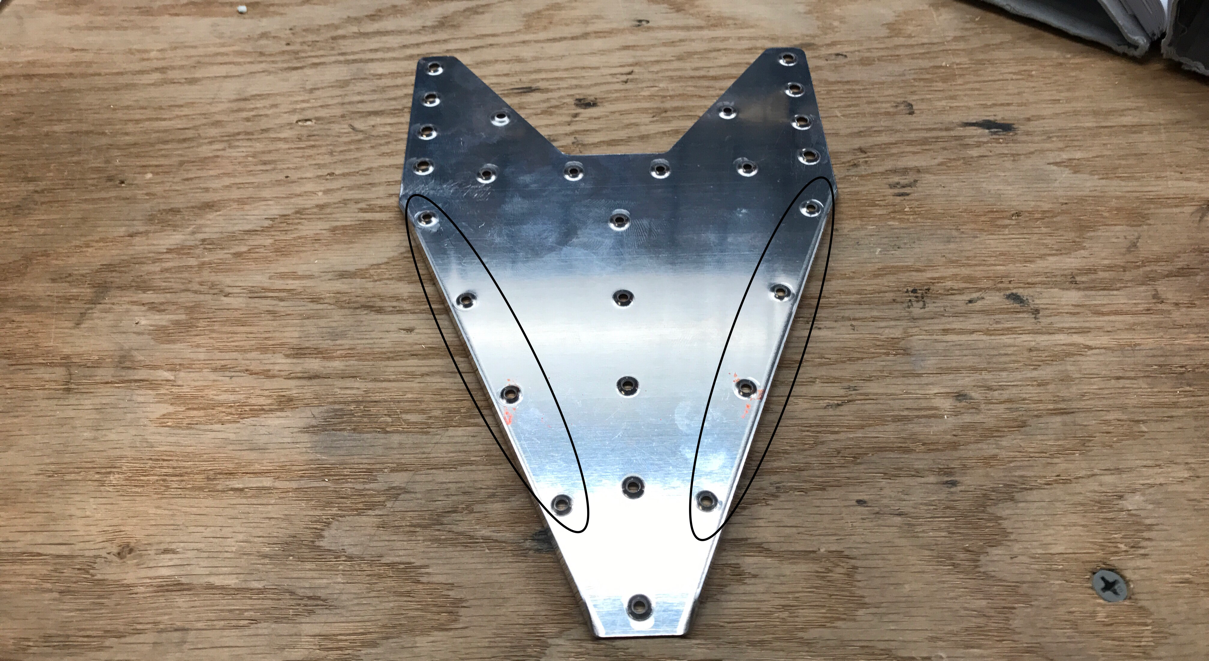

Here is a picture of the bottom of the Doubler after the #40 holes were dimpled (circled).

And the top side.

In Part 14, I started the riveting process of the bulkhead assembly below. I set the 18 AN470AD4-8 rivets with 1/8 cupped set and pneumatic squeezer. The same 1/8 cup set manufactured to set #4 universal rivets is to big for the heads of a 3/32 (#3) rivet. So, I ordered a smaller 3/32 (#3) cup set from Cleaveleand Aircraft Tool. After I received the cupped set in the mail, I finished setting the remaining AN470AD3-4 and AN470AD3-3.5 rivets in the bulkhead assembly.....as shown below.